Your complete guide to probiotic yogurts

Probiotic yogurts have become very popular thanks to their benefits for digestive health. In this article, we’ll answer the most common questions about these yogurts: What are probiotics? What benefits do they offer? What is the best probiotic yogurt? Are they suitable for children? Do they help with digestive issues like constipation or irritable bowel syndrome? And what probiotic yogurt brands are recommended?

All of this is explained in clear and accessible Language, perfect for any reader interested in improving their diet and gut health.

What are probiotics?

Probiotics are live microorganisms commonly referred to as “good bacteria” that, when consumed in adequate amounts, provide health benefits to the body. In other words, they are beneficial microbes that naturally live in our intestines and help keep them healthy. They are found naturally in fermented foods such as yogurt, kefir, sauerkraut, and certain cheeses, as well as in dietary supplements.

In the case of yogurt, it is naturally a probiotic food because during its production, milk is fermented with bacterial strains—usually Lactobacillus bulgaricus and Streptococcus thermophilus. Many yogurts are also enriched with additional probiotic strains. These bacteria survive in the intestine in sufficient quantities and help balance the intestinal microbiota, or gut flora, by competing with harmful microbes and supporting digestive health.

In short, probiotics are the friendly microorganisms found in yogurt and other fermented foods that, when ingested, can help restore the balance of gut flora and support various functions of the body.

What are the benefits of probiotic yogurts?

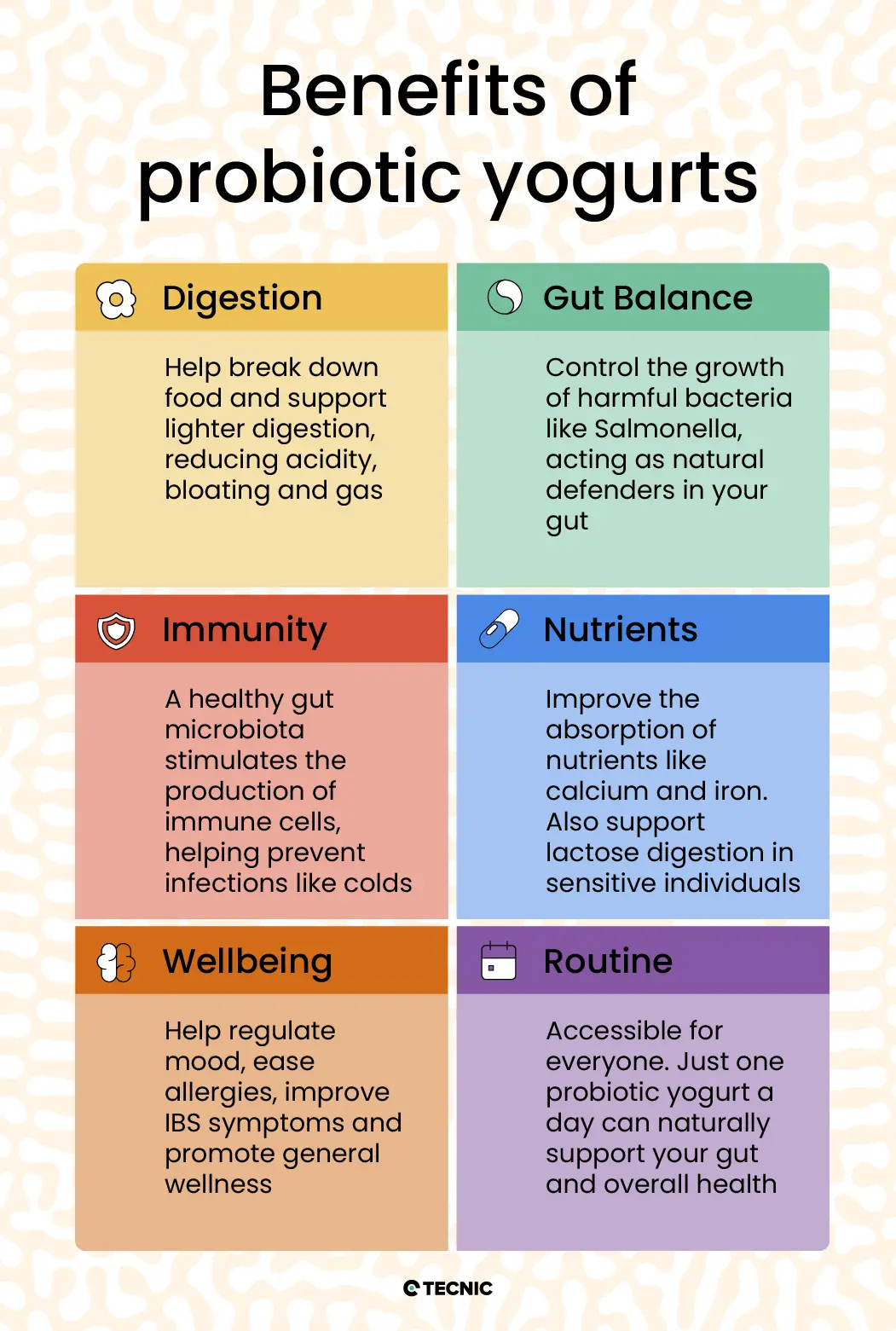

Consuming yogurts with probiotics on a regular basis can have multiple health benefits. By incorporating “good bacteria” into your diet, you are supporting your intestinal ecosystem, which has a positive impact on your entire body. Below, we summarize some of the main benefits of probiotics in yogurt:

- They improve digestion and intestinal transit: They help break down food and make digestion easier, relieving discomfort such as acidity or bloating. They also regulate intestinal transit, helping with both constipation and diarrhea by balancing the gut flora. Many people report lighter, more regular digestion when consuming probiotic yogurt daily.

- They maintain a balanced gut microbiota: Probiotics limit the growth of harmful bacteria in the gut, helping prevent gastrointestinal infections. Simply put, they act as “defenders” in the gut that stop harmful microbes like E. coli or Salmonella from multiplying and causing diarrhea or other digestive problems.

- They strengthen the immune system: A large portion of our immune defenses resides in the intestine, and probiotics help strengthen them. A healthy gut flora is known to stimulate the body’s immune response. For example, certain probiotics increase the production of defensive cells (like macrophages), which can lead to fewer common infections such as colds or gastroenteritis.

- They enhance nutrient absorption: The beneficial bacteria in yogurt help improve the absorption of certain vitamins and minerals. For instance, they aid in the assimilation of vitamin B, calcium, iron, and other essential nutrients. They also help digest lactose in people with mild intolerance, making it easier to consume dairy products.

- They may benefit other areas of health: A balanced gut is associated with positive effects beyond digestion. Studies suggest that regularly consuming probiotics could be linked to a lower risk of certain intestinal diseases (like colitis or irritable bowel syndrome), improvements in some cases of allergies and eczema, and even positive effects on mood due to the gut-brain connection. While much research is still ongoing, maintaining a healthy microbiota appears to play a key role in overall wellness.

In short, probiotic yogurt is a powerful ally for digestive health: it protects and balances your gut flora, improves daily digestion, helps you absorb more nutrients from food, and strengthens your natural defenses. And all of that in a delicious, accessible food like yogurt!

What is the best probiotic yogurt?

Plain, unsweetened yogurt made with milk and live cultures is considered the healthiest option. When it comes to the “best” probiotic yogurt, nutritionists agree that quality and composition matter more than the brand. A good probiotic yogurt should be as simple as possible: ideally plain, whole-milk, with no added sugars, made only from milk and live bacterial cultures. This type of traditional yogurt contains the necessary beneficial bacteria (like lactobacilli and bifidobacteria) without unnecessary additives like sugar, artificial sweeteners, colorants, or thickeners.

Why is plain yogurt usually the best?

Because without sugar or additives, its probiotic and nutritional benefits remain intact. Also, the natural fat in whole-milk yogurt is not harmful—on the contrary, it provides fat-soluble vitamins such as vitamin D, which are often lost in low-fat versions. Natural yogurt provides protein, calcium, and probiotics, and its neutral flavor makes it easy to pair with fresh fruit, honey, or cereals if you want a healthier touch of sweetness.

Plain Greek yogurt is also an excellent probiotic option. Greek yogurt is a strained yogurt that’s creamier and higher in protein, while still containing beneficial active cultures. It’s always best to choose it without added sugar or flavors to make the most of its benefits. According to experts, the healthiest options on the market are first, traditional plain yogurt, and second, plain Greek yogurt—both without added sweeteners or syrups.

In summary, the best probiotic yogurt will be one that meets these criteria: simple ingredients (milk and live cultures), no added sugar, and preferably whole milk. Many brands offer yogurts labeled as “bifidus” or “probiotic,” but it’s always important to check the label: it should clearly state that it contains live and active cultures (some labels say “with live cultures” or specify the bacterial strains) and it shouldn’t be packed with sugar. A good-quality plain or Greek yogurt—even without fancy marketing—is already an excellent daily probiotic. If you want more flavor, just add chopped fruit or a bit of natural sweetener to keep it healthy.

Are probiotic yogurts good for children?

Yes, probiotic yogurts can also be beneficial for children—with some considerations. Yogurt is often one of the first dairy products introduced during infancy (once complementary feeding has started, usually between 6 and 9 months, always under pediatric guidance). Natural yogurts contain cultures that help digest lactose, making them well tolerated by many babies and children who can also benefit from their properties.

Probiotics in children work similarly to how they do in adults: they help maintain a balanced gut microbiota and a healthy digestive system. They may help prevent or reduce common childhood digestive issues such as diarrhea (including antibiotic-associated diarrhea), constipation, and colic. They also support the immune system: some studies suggest a slight reduction in the frequency of respiratory infections (like colds or ear infections) by improving gut defenses.

It’s important to choose yogurts appropriate for the child’s age. For young children, it’s best to offer whole-milk natural yogurt without added sugar (the milk fat is beneficial for their development). You can naturally sweeten it with mashed fruit if they prefer a sweeter taste. There are also yogurt products made especially for children, such as petit-suisse types (like Danonino) and child-friendly probiotic yogurts, usually sold in small portions with appealing flavors. These versions are safe and designed for young kids, though it’s important to keep an eye on the sugar content in commercial varieties.

Brands like Danimals (the U.S. version of Danonino) and drinkable yogurts for kids contain probiotics and are quite popular. Even classic yogurt tubes or pouches (like Yoplait Go-Gurt) contain live cultures. In general, offering a child one yogurt a day can be an easy way to improve their digestive health while providing calcium and protein.

As always, if there are specific concerns—such as a compromised immune system or a medical condition—it’s best to consult a pediatrician. But for the majority of healthy children, including probiotic yogurts in their diet is safe and beneficial, helping to establish healthy eating habits from an early age. In fact, many manufacturers indicate that their probiotic yogurts are suitable for the whole family, including children, as part of a balanced diet.

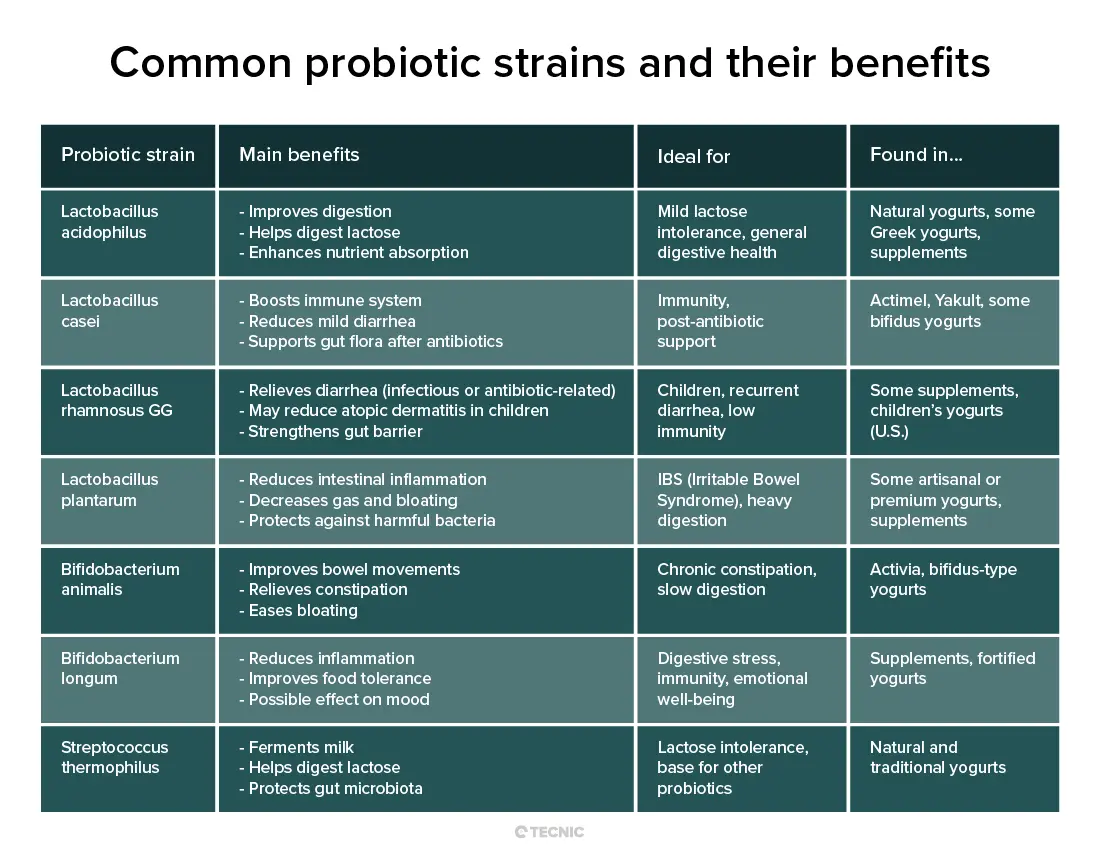

What types of probiotic strains are there and what are they used for?

When we talk about probiotics, we’re not referring to just one type of bacteria. There are many different probiotic strains, each with its own unique properties. Just like not all medications treat the same condition, not all probiotics serve the same purpose in the body. Understanding the most common strains and their benefits can help you choose the best yogurt or supplement depending on your needs—whether it’s improving digestion, boosting immunity, or relieving gas.

Below is a summary of the most widely used probiotic strains in yogurts and fermented products, along with what they do:

Can probiotic yogurts relieve constipation and irritable bowel syndrome (IBS)?

Many people consume probiotic yogurts looking for relief from specific digestive issues such as chronic constipation or irritable bowel syndrome (IBS). But what does the evidence say?

Probiotics and constipation: Several studies suggest that certain probiotic strains help improve bowel regularity. In people with chronic functional constipation (that is, long-standing constipation without an apparent organic cause), probiotics have been shown to reduce intestinal transit time (meaning they speed up how long it takes stool to move through the colon) and improve stool consistency and frequency.

In particular, strains like Bifidobacterium lactis stand out as allies against constipation: they’ve been shown to increase the number of beneficial bifidobacteria in the colon, resulting in more regular and easier bowel movements. Other bacteria such as Lactobacillus casei and L. reuteri have also demonstrated positive effects in clinical studies, helping relieve constipation symptoms.Many probiotic yogurts (such as Activia by Danone) contain these specific strains designed to improve gut transit. In fact, daily consumption of bifidus yogurts is popularly associated with “helping you go to the bathroom more regularly,” which is also backed by science—at least in mild cases.Of course, every body is different, but including a probiotic yogurt in your diet, along with enough fiber and water, can be a useful and natural way to regulate your bowel movements.

- Probiotics and irritable bowel syndrome (IBS): IBS is a common digestive disorder characterized by abdominal pain, bloating, gas, and irregular bowel habits (sometimes diarrhea, sometimes constipation, or both alternating). There is no definitive cure, but diet and microbiota play a major role in its symptoms. In this context, probiotics may offer support to some individuals with IBS. Several studies and meta-analyses have concluded that certain probiotics bring modest yet significant improvements in IBS symptoms like abdominal pain and bloating, as well as reduced flatulence.

For example, strains of Bifidobacterium (breve, longum, infantis) and Lactobacillus (acidophilus, casei, plantarum) have been linked to reduced discomfort and less gas in IBS patients.

All yogurts contain live Lactobacillus, and some also include Bifidobacterium, so they could contribute to those improvements. While not a magic cure (IBS requires a broader approach—such as FODMAP diet in some cases, stress management, etc.), eating probiotic yogurt daily may help reduce symptoms in some people. It’s a simple, safe option that can complement other gut care strategies.

In short, probiotic yogurts can be helpful both for relieving constipation and for improving certain symptoms of IBS, thanks to their regulating effect on gut flora and intestinal function. Their effects vary depending on the person and the specific probiotic strain, but scientific evidence supports their use as a complementary tool in managing digestive issues. If you suffer from chronic constipation or IBS, adding a probiotic yogurt to your daily routine is a simple step that could bring relief—especially when combined with a balanced diet and guidance from your doctor or nutritionist.

What brands of probiotic yogurts are recommended?

There is a wide variety of yogurts enriched with probiotics on the market. Below, we list some popular probiotic yogurt brands both in Spain and internationally, along with their characteristics, to help you choose the one that best suits you or your family:

In summary, the best probiotic yogurt brands are those that offer products with a high count of live cultures and low sugar content. Activia is ideal if your goal is to improve digestive regularity; Chobani or Fage if you’re looking for a dense, high-protein yogurt with diverse strains; Yoplait or traditional yogurts if you want something for the whole family and easy to find; and options like Yakult or Actimel if you prefer a drinkable format to support your immunity or microbiota. You have many options to try and see which works best for you and your family!

Conclusion: Dare to take care of your digestive health with a yogurt a day

We’ve seen that their benefits range from improving daily digestion and gut flora to potentially boosting immunity and relieving certain digestive problems. Moreover, there are options for all tastes and ages—from children to older adults—across multiple brands and formats.

Something many people don’t know is that the probiotics we consume in yogurts are made thanks to biotechnology, specifically in bioreactors. These systems make it possible to grow beneficial bacterial strains in a controlled and safe way. Specialized companies like TECNIC, leaders in bioprocess solutions, manufacture bioreactors designed to produce microorganisms such as Lactobacillus and Bifidobacterium, which are found in probiotic yogurts. So, what ends up in your fridge starts much earlier in a highly technical and sterile environment, where science and technology work together to improve your digestive well-being.

As a final recommendation, remember to maintain a balanced and varied diet. Probiotics work best when part of an eating pattern rich in fiber, fruits, vegetables, and proper hydration. If you’re unsure which yogurt is right for you, or if you have a specific health condition, talk to a doctor or nutritionist. We hope this guide has answered your questions! Next time you're at the grocery store in front of the dairy section, you’ll know exactly what to look for.

Frequently Asked Questions (FAQ)

Probiotic yogurts support digestion, improve nutrient absorption, and help maintain a healthy gut microbiota.

Yes, daily consumption of probiotic yogurt is generally safe and may improve gut health and immune function over time.

Yogurts labeled with live and active cultures, especially those with Lactobacillus and Bifidobacterium strains, tend to have the highest probiotic content.

Yes, probiotic yogurts can support digestive health and immunity in children when consumed as part of a balanced diet.

Yes, eating probiotic yogurt at night is safe and may support overnight digestion and gut function.

Signs include improved digestion, reduced bloating, better bowel movements and overall gut comfort.

Some Greek yogurts contain probiotics, but it's important to check the label for live and active cultures.

References

Hill, C., Guarner, F., Reid, G., Gibson, G. R., Merenstein, D. J., Pot, B., ... & Sanders, M. E. (2014). The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nature Reviews Gastroenterology & Hepatology, 11(8), 506–514.

- Dimidi, E., Christodoulides, S., Scott, S. M., & Whelan, K. (2017). Mechanisms of action of probiotics and the gastrointestinal microbiota on gut motility and constipation. Advances in Nutrition, 8(3), 484–494

- National Health Service (NHS). (n.d.). Probiotics. NHS.

- Ringel, Y., & Ringel-Kulka, T. (2011). The rationale and clinical effectiveness of probiotics in irritable bowel syndrome. Journal of Clinical Gastroenterology, 45(Suppl), S145–S148.